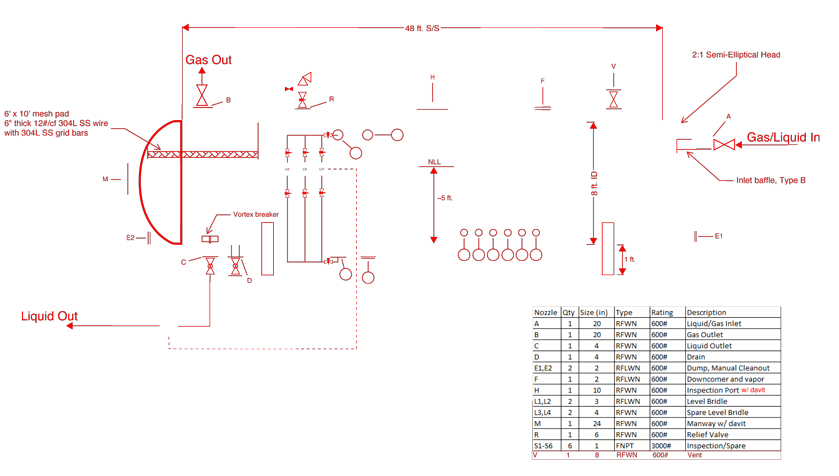

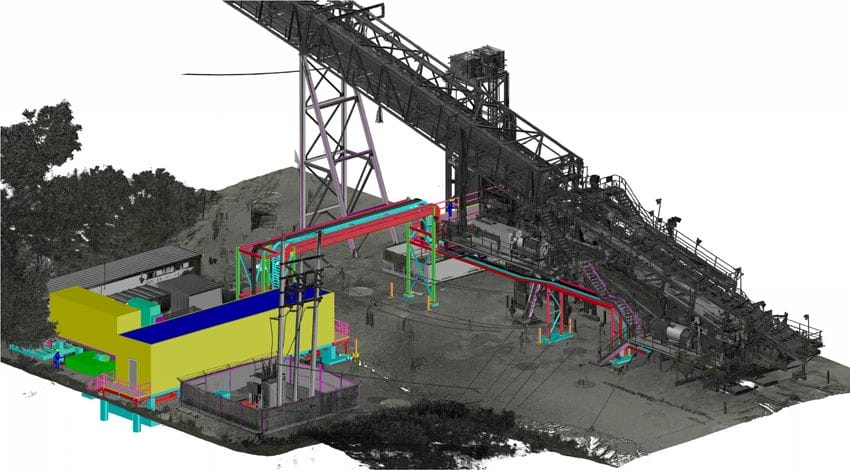

JEPCO was selected to provide engineering services required to install a new slug catcher. An existing underground slug catcher was nearing the end of its reliable life. The client desired to install a new, above ground, slug catcher in such a way that minimal downtime was experienced as the existing slug catcher would be taken off-line. JEPCO began the engineering work by modifying existing P&IDs, identifying new tie points and providing new relief valve calculations. Once data sheets and drawings were developed, JEPCO obtained vendor bids, created bid tabs, and provided the information to the procurement team. As part of the scope of work, JEPCO engineered and designed associated piping, civil/structural, and electrical/instrumentation. To minimize downtime, JEPCO utilized 3D scanning to develop a cut-over plan from the original underground slug-catcher to the new above ground vessel.

All disciplines process, piping/mechanical, civil/structural and electrical and instrumentation were available for home office support and site visits as necessary during construction and start-up.

JEPCO understands the importance of how a team approach has a positive effect on the overall success of a project. This project was no exception. We believe it is even more important that we work together to understand the design basis for the project in order to identify the needs of the client while keeping safety, cost, and schedule as major considerations.