JEPCO was responsible for all project engineering activities with regards to the schedule, budget, and staffing. The skilled team at JEPCO met the challenge efficiently and completed the evolving work scope on time to support the successful kick-off of the project construction effort.

For this project, we partnered with Savage to design, procure and construct a polyethylene pellet loading facility along with supporting infrastructure of a maintenance building, administrative building and relevant utilities for a large gulf coast operator. We provided all disciplines in-house to support this project including: Process, Piping, Mechanical, Civil/Structural, Electrical and Instrumentation as well as the automation piece. Savage will own and operate the rail terminal and loading facility.

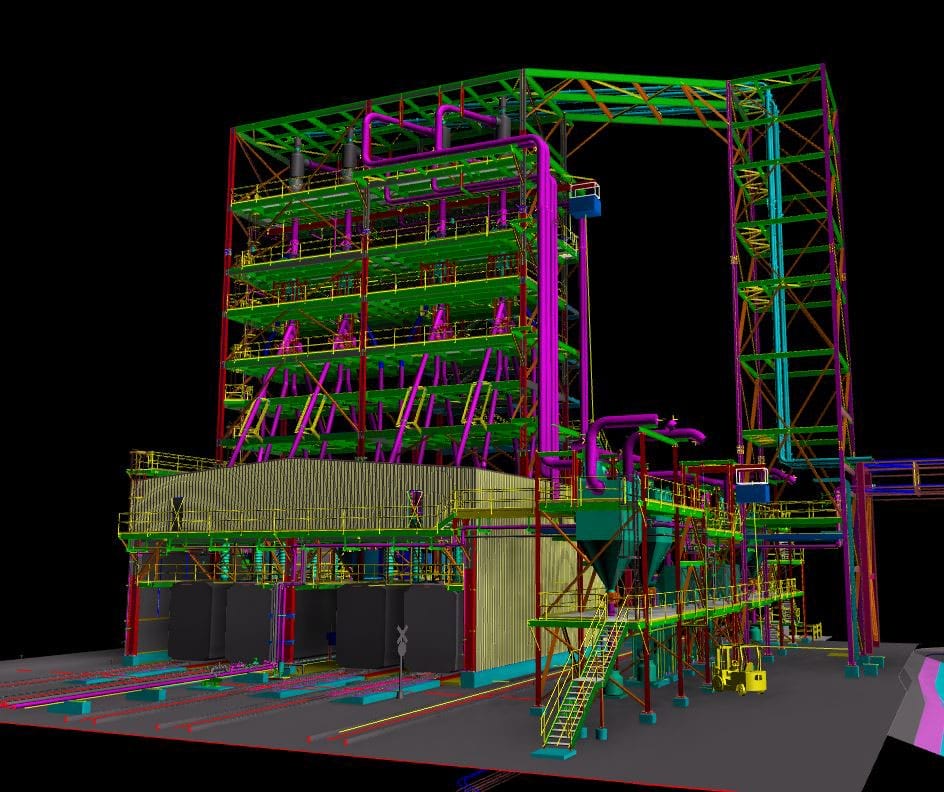

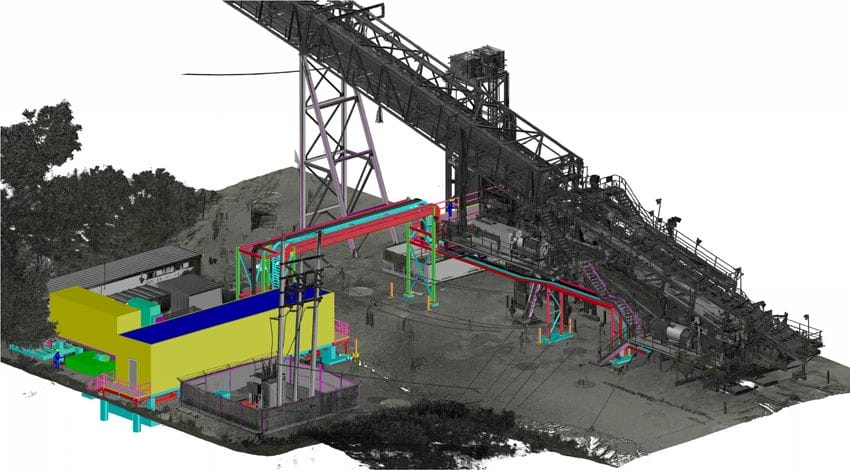

Below in the picture to the left, is the computer aided 3D design (done in CADWorx), of the entire polyethylene pellet loading facility structure. The photo on the right shows the facility nearing completion. The loadout facility was designed to load one rail car at time on each of the four tracks. The polyethylene pellets are pneumatically conveyed from inside the operator’s facility, passing through the pipes on the righthand side tower structure (not yet installed in right photo). A baghouse per conveyance line was installed to capture any fugitive dusts. The space between the main load out facility and the tower structure was to allow for a ‘run-around’ rail line. Locomotives can move freely between the entry and exit of the loading facility. This was a very successful project for everyone, completed on time and on budget. The link to the model is below:

Below is the computer aided 3D. The photo following shows the facility nearing completion.

JEPCO was engaged to provide the design, procurement support and construction execution consulting services to support specific portions of a large project being constructed in the Texas Gulf Coast region. JEPCO developed an in-depth and very detailed work scope and an associated total installed cost (TIC) that included engineering, procurement, and construction (EPC) for the project scope. The initial engineering included Process, Civil, Structural, Mechanical, Electrical, Instrumentation, and Automation Engineering portion of the project. The scope deliverable list included the following:

Car Preparation and Loading Facilities

- Civil Design

- Grading

- Foundations

- Sewer Piping

- Process Water Piping

- Structural Design

- Structural Steel

- Stairs

- Grating and Handrail

- Roofing and Siding

- Electrical Design

- MCC Equipment Specifications

- Electrical Load List

- Power, Cable Tray and Conduit Plans

- Panel Schedules

- Lighting Drawings

- Conduit and Cable List

- Rail Scales and RFID Readers

Administration Building & Maintenance Buildings

- Civil Design

- Grading

- Foundations

- Utilities to Building

- Architectural Design

- Specifications for Pre-engineered Building

- Floor Plan

- Elevations

- Associated Site Electrical

- Grounding Drawings for all Buildings

- Electrical Load Lists

- Duct Bank Plans

- Power Distribution Plans

- Fiber Distribution Interconnect Drawings

- Overhead Power Distribution

- Single Lines

- Coordination with other EPCs

- Conduit and Cable Lists