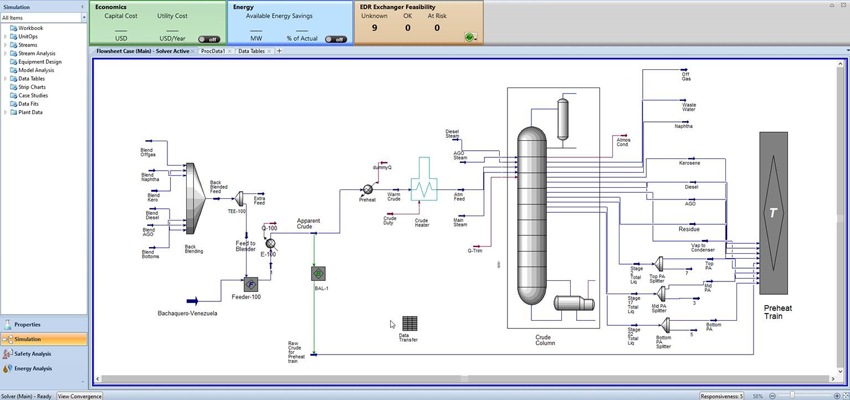

JEPCO recently performed extensive Hysys modeling in order to debottleneck a crude unit for a Gulf Coast refiner to gain an additional 10,000 barrels per day. We created PFDs for the proposed system and developed a 50% TIC.

Scope of Work

This included:

- Heat integration, booster pumps, an overhead compression system, increased steam capacity and a new pre-flash column.

- As a continuation of the debottlenecking evaluation, JEPCO performed process modeling and economic evaluation for this option.

- JEPCO researched optimizing yields at the refinery for maximum profit. This involved various levels of capital investment. Deliverables for this project included: a yield table, operating conditions, a converged model and a preliminary list of new or modified equipment.

- Most recently, JEPCO investigated the impact of opportunistic crudes on the proposed system and identified additional equipment that would be required to handle the change in product distribution.

JEPCO has performed many projects specifically in crude units such as evaluating heaters, updating BMS, exchanger replacement, relief valve evaluations, etc., for multiple domestic refiners.

JEPCO’s process engineering expertise and knowledge of debottlenecking, optimizing yields and the impact of utilizing various crude slates has been crucial in assisting the refiner in choosing the best path forward for their business.