Taking A Refiner From Severe Corrosion to Safety

Problem: A refiner was experiencing frequent corrosion and scaling issues within its various cooling water systems. One system experienced an acid cooler failure after only seven months in service, resulting in a unit shutdown and replacement of every cooling water exchanger. Unknown at the time by the refiner, the rapid corrosion was due to misapplied cooling water chemical treatment.

Operational Impact: Cooling water chemical control parameters were not set properly to prevent corrosion in the cooling system. The unit had just come out of a turnaround, where every heat exchanger had been replaced. Startup cooling water passivation provided poor results, with high iron levels for weeks after startup. The chemical provider was unaware that the system was operating under extreme corrosion conditions. After seven months, a main acid cooler leaked acid into the cooling water, resulting in a unit shutdown and replacement of every cooling water exchanger.

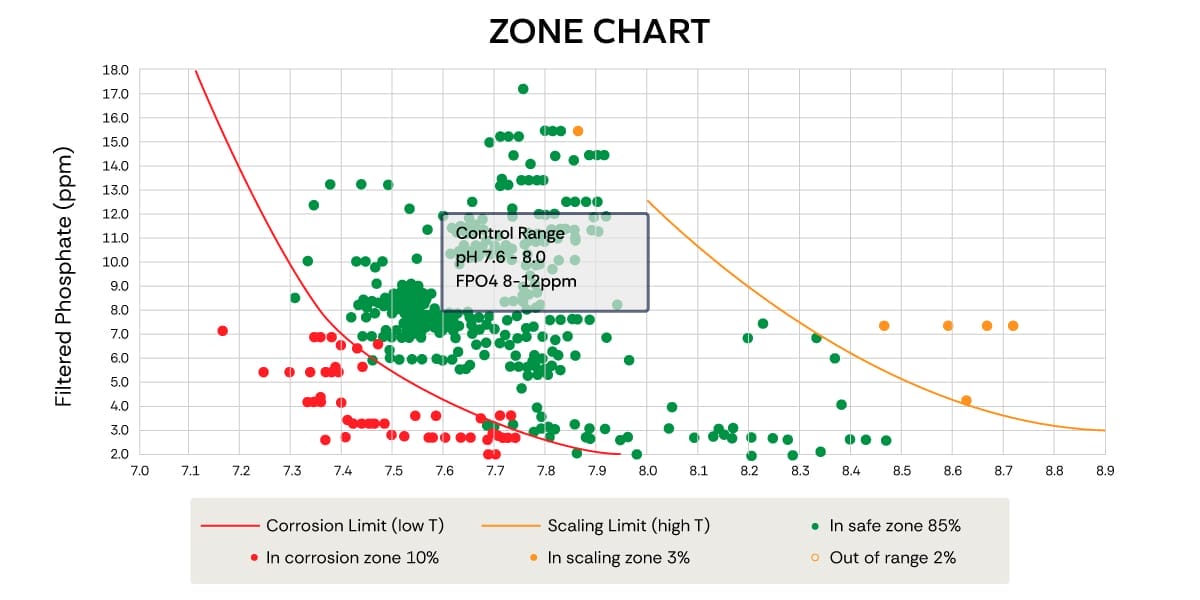

Solution/Action Plan: The JEPCO team utilized French Creek, a water treatment software tool, to identify the actual cooling water treatment conditions and learn why the exchangers corroded so rapidly. French Creek software calculates the ability of the water chemistry to prevent corrosion and scale while determining safe operating ranges. French Creek can also help the water treater determine safe operating conditions of the cooling water system based on makeup water quality, exchanger operating conditions and chemical control capability.

Deliverables: The JEPCO team determined the recommended chemical control parameters for this cooling system, resulting in operating targets that will provide protection from both scale and corrosion conditions. The team also developed an Excel version of the French Creek software program so that unit engineers can monitor refinery lab or chemical provider chemical data to determine the time each cooling water exchanger is operating in the corrosion, safe or scaling zones. The tool allows a unit engineer to understand the cooling water test data provided by the chemical vendor in the context of performance risk.

Results: This significant improvement not only enhanced system reliability but also led to substantial cost savings for our client by reducing corrosion-related maintenance, repairs, and downtime.