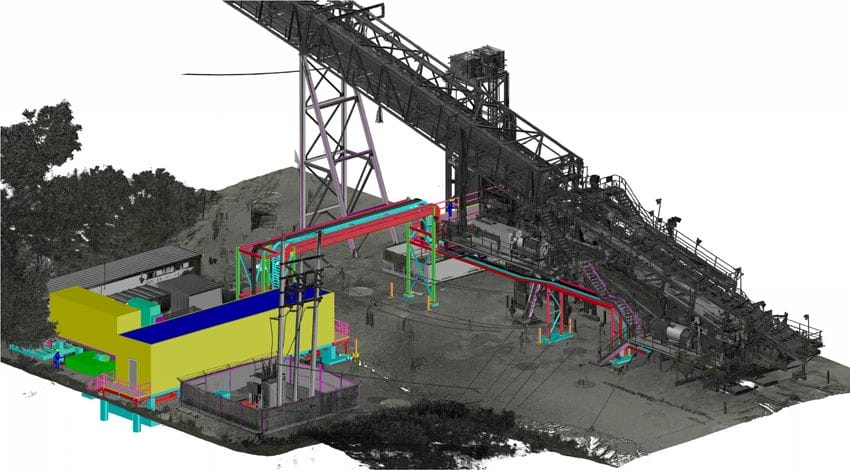

JEPCO was the chosen engineering firm to provide detailed engineering services related to the replacement of an existing conveyor transfer e-house for a large metal and mining corporation. The scope of work included all engineering services required to replace the electrical house and equipment.

The driving force behind this project was to install VFD control of the conveyors and upgrade the control system to Contrologix which is the standard automation platforms at the site.

JEPCO assumed responsibility for a critical aspect of the project which was a well-executed factory accepted test (FAT), at the e-house manufacturer’s facility. This FAT was a coordination/collaboration between the client, the equipment manufacturers and JEPCO. As a brownfield project, we took multiple inspection and investigative trips to site to verify the existing wiring, routing and undocumented changes. Attention to detail and a well-executed FAT were critical to completion of the project in a timely manner.

Throughout the project, JEPCO supported our client’s project objectives by focusing on engineering activities for the e-house replacement including procurement of critical path equipment and scheduling support of shut down activities. JEPCO partnered with the client throughout the project to provide an updated execution plan that exceed the goals and the objectives of the project.